TPU Recommended Process

●Pre-Drying

1.Before molding, the TPU raw material must be dried regardless whether it is properly packed or not.

2.Because of easier moisture absorpting and hydrolysis characteristics,if the TPU raw material is not fully dried it tends to cause difficult processing, a poor surface of the finished components and the lowering of mechanical properties.The refore,TPU pellets must be dried till the water content becomes lower than 200 ppm(0.02%)before molding.

3. If the pigment or color masterbatch is used,they must be fully mixed with TPU pellets then drying together.

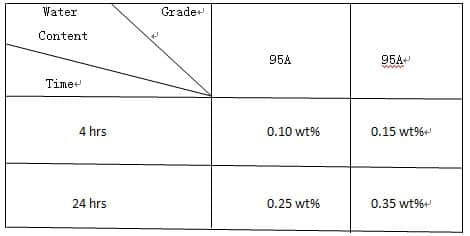

4.Due to the chemical structure,the TPU pellets absorbs moisture very quickly when exposing pellets in the air.Especially the ether-type TPU absorbs moisture quicker than the ester-type TPU.For example,U-95A and

UE-95A grades,both are compared in Table1 under 25℃ and 50% relative humidity.

5.Regardless of conventional circulating air hopper or dehumidifier,both can be used for TPU drying.Listed below are the recommended drying conditions:

Shore 60A~80A : 90~100℃, 3~5hrs。

Shore 85A~98A :100~105℃, 3~5hrs。

Shore 60D~71D :105~110℃,3~5hrs。

●Recycing of Scrap

The sprues and runners can be crushed for mixing with virgin material,but one more drying process would be required before use.To meet certain mechanical properties requirement,the recycled scraps cannot be more than 30wt% of the total material.Besides the recycled scraps should not be stored too long time.It is the best to be dried immediately for use.-

●Post-Treatment

1.The post-treatment can get the optimal and stale mechanical properties for TPU.Such process is required for some high-performance finished products and the item that needs to know the property result immediately.

2.Listed in Table 2 are the recommend post-treatment conditions.

3.By exposing the injection or extrusion finished products at 25℃ for about 4~5 weeks,the mechanical properties that obtained are very close to that obtained from the post-treatment.

●Processing Surrounding and Environmental Protection Suggestions

Same as general plastics, the Utechllanr®TPU tends to decompose zbove certain temperature. When the moke is produced during processing the fully dried TPU pellets,it means the TPU raw material has already been decomposed.Normally,the Utechllanr®TPU starts to decompose slowly upon reaching 230℃ and so the operation room must be equipped with effective ventilation and air discharge equipment. The Utechllanr®TPU will not contaminate the environment and the waste that cannot be processed any longer can be disposed in ordinary landfill site or incineration plant,except that the environment protection regulations must be observed.

● Package &Storage

1. Our TPU pellets is packed in 25kgs multi-layer paper A1 bag for loading in the PE film .The water content of the original TPU pellets is below 200ppm(0.02%).

2. Our TPU pellets shape is available in two types.One of them is rice-like shape ,the suffic is marked as 10 and the other ,cylindrical shape which is marked as 20 on the suffix.

3. The shelf life of well-sealed package TPU should be around 1 year .Beacause TPU is a kind of material that is easy to moisture absorption and hydrolysis,so it is recommended to have them molded within 2 years after the TPU has been produced and be stored in a ventilated, dry and away from sunshine.

● Injection Molding Machine

As shown in the above figure ,the single-screw 3-section injection machine is more suitable for the TPU injection.Comparing to other plastics,it tends to produce high shear stress in the screw barrel owing to the high viscosity during melting so as to damage the properties of TPU.Therefore,the screw having L/D ratio around 16~20 and compression ratio around 2.0~2.5 is selected for using in the injection of TPU.

● Injection Temperature

Shown in Table 3 is the recommended injection temperatures which will be asjusted according to the size,thickness of the finished components and the dimension of injection machine.

● Mold Temperature

Normally,it is recommended to maintain the mold temperature between 25℃ and 45℃.For some special purposes,e.g.processing the transparent grades,the cold water can be flowed through the pipeline inside the mold to keep the temperature at around 10℃ so as to achieve transparency and reduce cycle time.

● Shrinkage

- As TPU is obtained through the monomers quantitative polymerization process and it would become semi-sticky gel type when melted,its shrinkage is easy to change by the finished product designed(e.g. gate,thickness and shape) and injection conditions (injection temp,injection pressure and mold temp.). Therefore, it would be very difficult to precisely estimate the shrinkage of finished product.

- The shrinkage of the Table 4 grades can be used as a reference of the mold design.

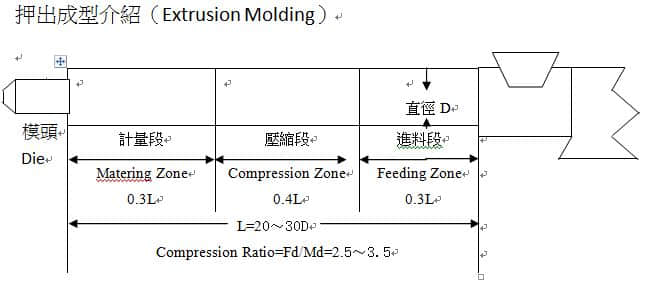

● Extrusion Molding Machine

As shown the above figure,the single-screw 3-section extrusion machine which has L/D about 20~30 and compression ratio about 2.5~3.5 is application for the TPU extrusion .The pitch of screw is equal to diameter of screw.Shallow threads screw is better than deep threads screw and the gap between the screw and the barrel is approx.1.1~0.2mm.Indeally,the screw shall be designed to avoid overheat due to vigorous friction which causes the decomposition and lowers mechanical properties.For this reason,the screw revolving speed should be set between 30rpm and50rpm according to the diameter of the screw.

● Breaker and Screen Pack

According to the size of screw diameter,the hole of the breaker should be approx.1.5~5.0mm and uses two pieces of 400 mesh/cm2 filters interlaced with two pieces of 900 mesh/cm2 filters to achieve the optimal effect.For blow film,much finer screen pack must be used.

● Extrusion Temperature

Listed in Table 5 is the suggested extrusion temperatures

● Cleaning of Extrusion Machine

If the machine will be put aside for a long time,the PS or HDPE can be used to clean the screw and barrel .For the die and adapter,the accumulated scorch substance should be cleand after a certain period.

● Die Design

To achieve smoother flow of the TPU melt and easier cleaning of die,blind angle should be avoided upon designing the die.Longer die must be used for the pipe or irregular extrusion to obtain much steadier extrusion apart from reducing the shear stress.The length of die shall be 2to 4 times of the nozzle diameter.

● Cooling and Forming

Normally,the cooling tank of TPU is longer than the general plastics and the length will be decided according to the TPU grades,extrusion shape,profile and screw revolving speed.Beacause the friction coefficient of TPU is normally higher than general plastics,so it would be more difficult for forming.The higher hardness TPU is easier to form than that of the lower hardness.